|

Test loads: Depending on the models - From 1 to 3000 kgf (From 9,807 to 29421 N) Rockwell ISO 6508 / ASTM E-18: HRA - HRB - HRC - HRD - HRF - HRG - HRL - HRM - HRR / HRN - HRT

Brinell HBW e HBWT ISO 6506 / ASTM E-10: HBW1/30 - HBW2.5/15.625 - HBW2.5/31.25 - HBW2.5/62.5 - HBW2.5/187.5 - HBW5/25 - HRW5/62,5 - HBW5/125 - HBW5/250 - HBW5/750 - HBW10/100 - HBW10/250 - HBW10/500 - HBW10/1000 - HBW10/1500 - HBW10/3000 Vickers ISO 6507 / ASTM E-384 - Knoop ISO 4545: HV1 - HV2 - HV3 - HV5 - HV10 - HV20 - HV30 - HV50 - HV100

|

|

ONLY ONE INPUT FOR THE ENTIRE TEST CYCLE |

|

CLOSED LOOP (PAT. AFFRI) |

|

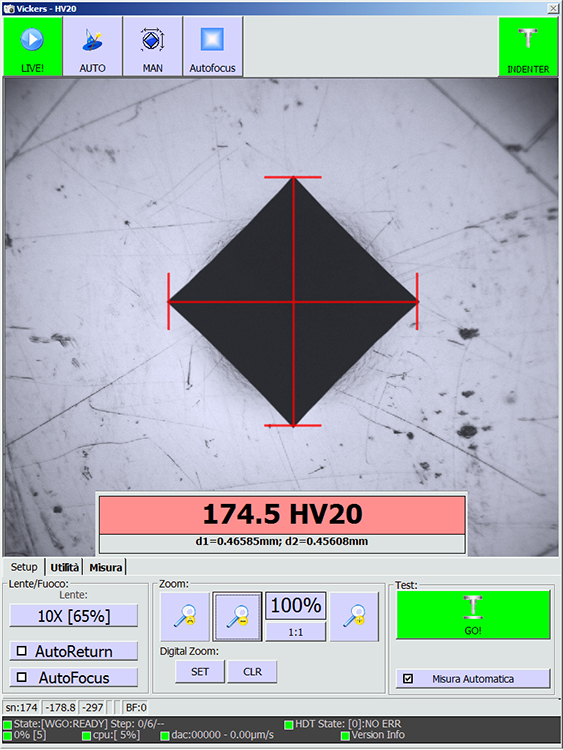

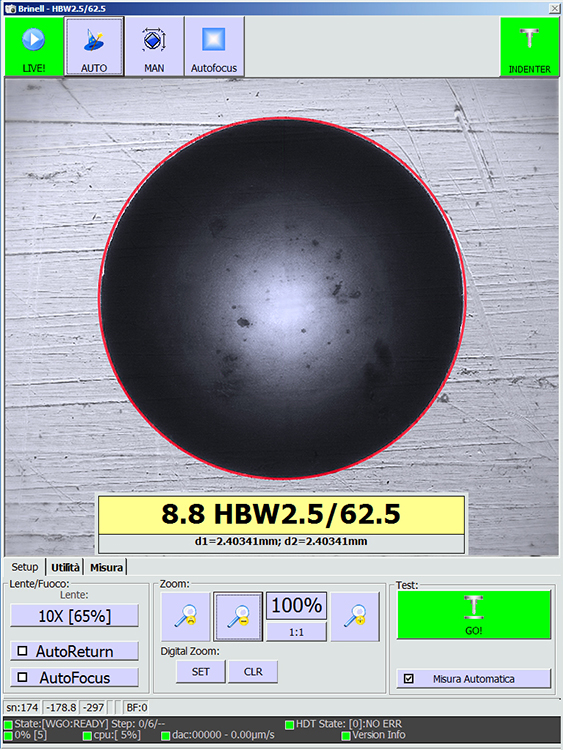

The hardness tester’s head moves down until contact is made, clamps the piece, applies the force and make the indentation. The software will move to the camera view mode where the indent is automatically measured. |

|

Closed loop load cells control load forces with a frequency of 1 khz, assuring perfect linearity in every range. Results are not affected by any structural deflection, misalignment or vibration. |

|

MOTORIZED HEAD |

|

WIDE WORKHOLDER |

|

Automatic movements with automatic stop when contact is made. Up to 300 mm of motorized vertical stroke. The approach of the head to the peace and not the opposite allows more accurate, scable and safe measurements. |

|

Supports masses beyond 2000 kg and special fixtures or anviling. Hardness measurements on bulky and irregular test pieces which cannot be easily reached by the regular bench hardness testers. |

|

CLAMPING SYSTEM (PAT. AFFRI) |

|

MOTORIZED TURRET (INDENTER/OBJECTIVE) |

|

Secure contact with the specimen is always mantained, even in the unlikely event of any specimen movement during the operation cycle. The clamping system assures perfect stability of any test piece throughout the test cycle. |

|

One slot for an indenter and one slot for an objective. Auto-rotating and auto-tool-switching for a complete automatic measurement cycle. |

|

SOFTWARE LD 250 |

|

|

|

|

|

|

|

|

|

|

LD 250

|

|||

|

Standards

|

EN-ISO 6506 / EN-ISO 6507 / EN-ISO 6508 / EN-ISO 2039 / EN-ISO 7619 / EN-ISO 868 / ASTM E-103 / ASTM E-18 / ASTM E-10 / ASTM E-384

|

||

|

XY Table

|

330 x 390 mm

|

||

|

Vertical head stroke

|

390 mm Motorized

|

||

|

Indenter and clamping hood stroke

|

0/30 mm Motorized

|

||

|

Depth capacity

|

190 mm

|

||

|

Reading

|

Focus: automatic and manual - Reading: automatic and manual

|

||

|

Preload

|

29.4 - 98.1 N (3 - 10 kgf)

|

||

|

Test loads

|

The hardness tester LD250 includes test loads up to 3000kg and can be customized depending on customer needs.

The standard version of the hardness tester includes test loads from 1 to 250 kgf (9.807 to 2452 N).

Vickers - Knoop: 9.807 - 19.60 - 29.42 - 49.03 - 98.07 - 196 - 294.2 - 490.35 - 980.7 N (1 - 2 - 3 - 5 - 10 - 20 - 30 - 50 - 100 kgf)

Brinell: 9.807 - 24.52 - 49.03 - 61.29 - 98.07 - 153.2 - 245.2 - 294.2 - 306.5 - 612.9 - 1226 - 1839 - 2452 - 4903 - 7355 - 9870 - 29421 N)

(1 - 2.5 - 5 - 6.25 - 10 - 15.6 - 25 - 30 - 31.2 - 62.5 - 125 - 187.5 kgf - 250 - 500 - 750 - 1000 - 3000 kgf)

Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf) Superficial Rockwell: 147.1 - 294.2 - 441.3 N (15 - 30 - 45 kgf)

|

||

|

Feasible tests

|

Rockwell: HRC - HRA - HRD - HRB - HRF - HRG - HRL - HRM - HRR Superficial Rockwell: HRN - HRT Brinell HBW (Depending on the models): HBW1/30 - HBW2.5/15.625 - HBW2.5/31.25 - HBW2.5/62.5 - HBW2.5/187.5 - HBW5/25 - HRW5/62.5 - HBW5/125 - HBW5/250 - HBW5/750 - HBW10/100 - HBW10/250 - HBW10/500 - HBW10/1000 - HBW10/1500 - HBW10/3000 Brinell HBWT (Depending on the models): HBT 2.5/62.5 - HBT 2.5/187.5 - HBT 5/125 - HBWT5/250 - HBWT5/750 - HBWT10/500 - HBWT10/1000 - HBWT10/1500 - HBWT10/3000 Vickers: HV1 - HV2 - HV3 - HV5 - HV10 - HV20 - HV30 - HV50 - HV100

|

||

|

Accuracy

|

Better than 0.5 %

|

||