|

Test loads: from 3 to 187,5 kgf (from 29,42 to 1839 N) Rockwell ISO 6508 / ASTM E-18: HRA - HRB - HRC - HRD - HRF - HRG - HRL - HRM - HRR / HRN - HRT HBWT Brinell ISO 6506 / ASTM E-10: HB 30 - HB 10 - HB 5 MPa (F/D2) Vickers ISO 6507 / ASTM E-384 (Only indentation): HV3 - HV10 - HV15 - HV30 - HV60 - HV100

|

|

USER FRIENDLY: |

|

||||

|

|

Pulling one single start lever the hardness result will appear in a few seconds. It is so simple and easy to use that there is no need for any particular preparation by the operator:

|

|||

|

THE AFFRI SYSTEM |

|

REPEATABILITY & REPRODUCIBILITY |

|||

|

Load forces are generated by a dynamometric load cell wich assures long term accuracy and eliminates problems associated with dead weight systems on traditional testers. Results are not affected by any structural deflection, misalignment or vibration.

|

|

Accurate measurements on the first test, even in extreme conditions, will eliminate the need for repeated tests. The R&R data is at the top of its class. |

|||

|

CLAMPING SYSTEM |

|

50mm OF INDENTER AND CLAMPING HOOD STROKE |

|||

|

Accurate hardness measurements even on unstable, dirty or oily samples. The clamping hood applies constant pressure and prevent from accidentaly samples movements during the test cycle. |

|

The measuring head follows the sample even in case of structural deflection. Easy and fast hardness measurements on different thicknesses without acting on the elevating screw. |

|||

|

|

||||

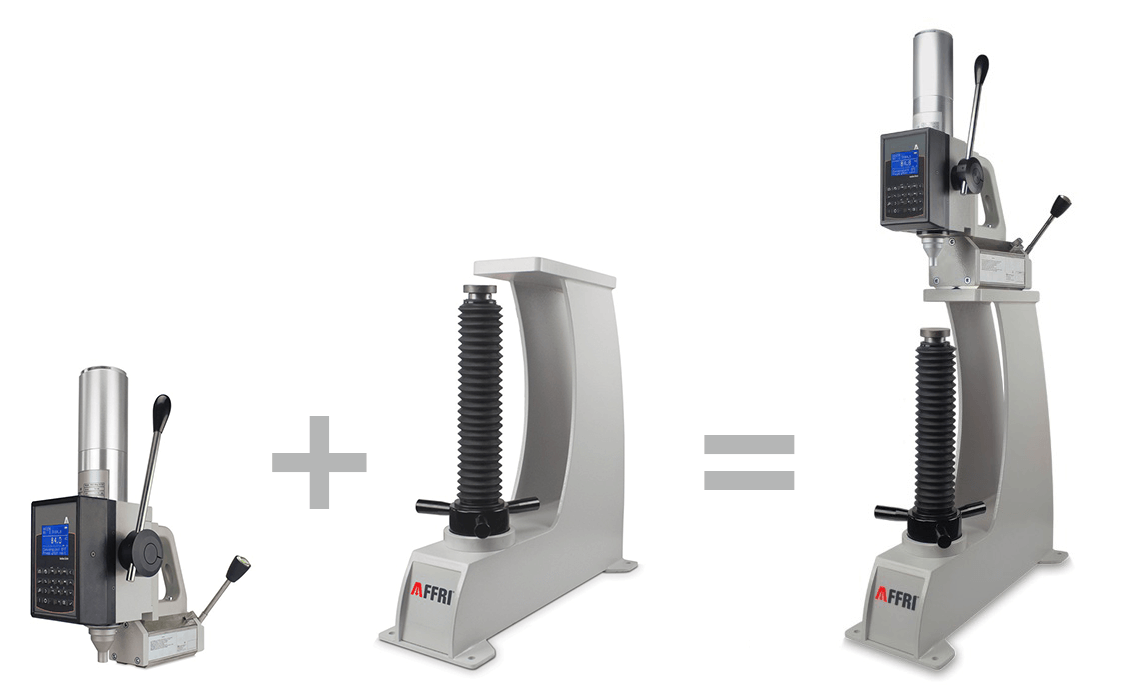

| FROM PORTABLE TO BENCH-TOP | ||||

|

To convert the RSD MAG from a portable to regular bench top hardness tester, based on your needs, it can be combined with two different size of stand support, 670H or 460L. This system fully conforms to hardness testing standards and allows testing in laboratory on small pieces and prepared samples without the need uf buying another hardness tester. Hardness measurements will result fast and easy as an AFFRI bench tester including the sample clamping system and the auto compensation of deflection thank's to indenter and clamping hood vertical stroke.

|

||||

|

||||

|

|

||||

| SOFTWARE RSD | ||||

|

The software controls the whole instrument during the entire cycle avoiding operator errors: |

||||

|

Set of the hardness test method |

Measurement settings |

Storable and printable statistics |

Results, averages and conversions |

|

|

|

||||

| HARDNESS TESTER MODELS: | ||||

|

RSDMAG/30-D2

RSDMAG/30-D4

|

RSDMAG/50-D2

RSDMAG/50-D4

|

RSDMAG/55-D2

RSDMAG/55-D4

|

RSDMAG/70-D2

RSDMAG/70-D4

|

RSDMAG/80-D2

RSDMAG/80-D4

|

|

COMPONENTS: |

||||

|

SMX30

300mm magnetic base for HR/HB measures up to 20mm sample’s thickness

|

SMX50

500mm magnetic base for HR/HB measures less than 20mm sample’s thickness

|

SMX55

Magnetic base with 10mm horizontal stroke sliding head for multi indentation

|

SMX70

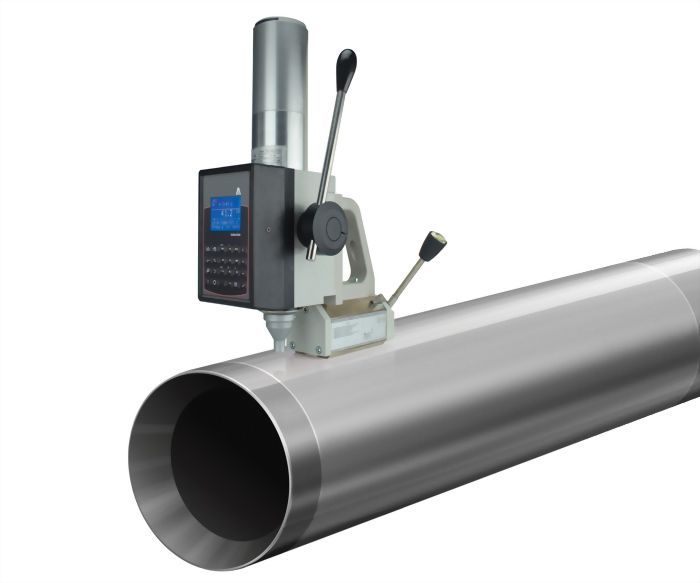

Double magnetic clamping base for big or small diameters round shape samples

|

SMX80

Chain clamping base for non ferrous samples

|

|

670H

High stand support:

Height capacity 390 mm Depth capacity 232 mm

|

460H

Regular stand support:

Height capacity 180 mm Depth capacity 204 mm

|

Tester head:

RSDMAG-D2

588,4-1839N(60-187,5kgf)

RSDMAG-D4

147,1-441,3N(15-45kgf)

|

The RSDMAG head can be assembled, as it is, on any of our manual hardness terster’s stand supports (206/330/331) |

|

|

RSDMAG D2

|

RSDMAG D4

|

|

|

Standards

|

EN-ISO 6506 / EN-ISO 6508 / ASTM E-18 / ASTM E-10

|

|

|

Indenter and clamping hood stroke

|

0/50 mm

|

|

|

Preload

|

RSD: 98.1 N (10 kgf)

|

RSD: 29.42 N (3 kgf)

|

|

Test loads

|

Rockwell:588.4 - 980.7 - 1471 (60 - 100 - 150 kgf) Vickers: 98.07 - 980.7 N (10 - 100 kgf)

Brinell: 98.07 - 612.9 - 1226 - 1839 N |

Superficial Rockwell:147.1 -294.2 -441.3(15 - 30 - 45 kgf) Vickersc: 29.42 - 294.2 N (3 - 30 kgf) Brinell: 153.2 - 294.2 - 306.5 N (15.625 - 30 - 31.2 kgf) |

|

Feasible tests

|

Rockwell: HRC - HRA - HRD - HRB - HRF - HRG - HRL - HRM - HRR

Superficial Rockwell: HRN + HRT

Brinell: HB30 - HB10 - HB5 - HB2.5 MPa (F/D2)

Vickers (Only indentation): HV3 - HV10 - HV30 - HV100

|

|

|

Accuracy

|

Better than 0.5 %

|

|